I bought a sewing machine. Actually, that day I bought three, but who’s counting.

Anyway, the machine I want to talk about was a Singer 66-16 from 1941. It was filthy, the cabinet was a vile mass of mold and mildew, but I instinctively knew there was a superb machine under the dirt and schmoo.

I was right, but I had no idea what can of worms I had opened.

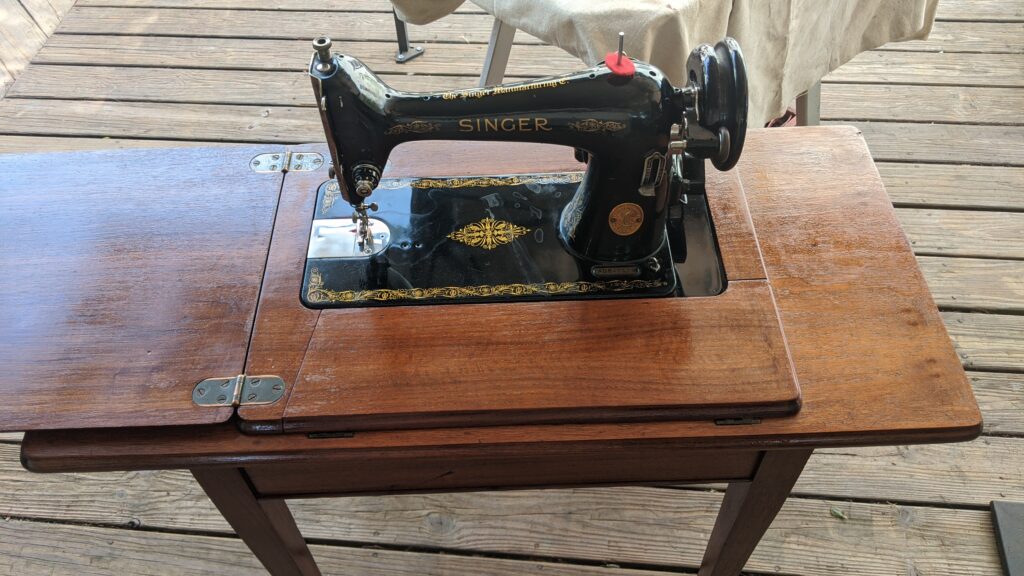

As found, Singer 66-16

The wiring was shot

I’d say on a scale of 1 to 10, this dirt and schmoo is an 11

Her list of flaws was pretty long. Besides the obvious cosmetic issues, she suffered from wiring that had completely deteriorated. She was also locked up, and locked up pretty bad too. Normally, I can free up a 66 or 99 pretty quickly, but not this time, this one was going to need some parts!

The first rule of fixing sewing machines (and most things mechanical) is DON’T FORCE ANYTHING! Find out WHY something is stuck using proper diagnostic procedures, then fix the issue. Well, someone in this machines past didn’t follow that rule and broke parts – important parts. I tried moving the handwheel and heard a distinctive clank. Taking off the cover on the needle bar end, I saw what I was up against and started disassembling the machine. Whomever it was that forced the handwheel had snapped the needle bar!

The broken remains of the needle bar and bushing

In case you don’t recognize the parts in the photo above, the part of the left is the needle bar bushing with the snapped off needle bar still inside. The part of the right is what’s left of the needle bar along with the clamp that holds it to the connecting rod. The needle bar was rusted solidly in the bushing.

So… What to do? I went to eBay and looked at the listings of my favorite supplier of sewing machine parts, and sure enough, he had both parts I needed. One problem… They were from different eras of Model 66. The needle bar he had was from the correct sub-variant, the 66-16. The bushing he had was from a 66-1 Red Eye from 1920. I ordered both, hoping they would fit.

They didn’t. They bushing from the Red Eye was oh so ever so slightly too small. I don’t have the proper machine tools to precisely bore out a hardened steel bushing, so I had to drop back 20 yards and punt. Luckily, I had saved the old parts. The next step was to attempt to salvage the original bushing.

2 hours and a lot of creative profanity later (Note: I’m tri-lingual, English, Sarcasm, and Profanity). the “new” needle bar was moving smoothly in the original bushing. The extraction process involved Aero-Kroil penetrating oil, and the judicious application of punches and hammer against the old needle bar. The bushing was actually in really good condition. There was minimal rust holding the needle bar in place, it was more crud than rust. Had the 200 pound gorilla that tried to force it just let it be, I would have had her freed up with no damage in very short order.

Once we knew the machine was going to be just fine, Liz stepped up to the plate and started tackling the cabinet.

Liz sanding the cabinetry…

She spent hours sanding, scraping, and stripping what was left of the finish from the cabinet. She also used a lot of A-1 Kerosene killing and cleaning off the mold and mildew. Once that was accomplished, the carcass was stained and new lacquer was applied. Liz did a great job on the cabinet, and I never even asked her to help, she just wanted to be a part of the rebirth of a classic.

There is still a lot of finishing work to be done, but we just wanted to see the machine in the cabinet for the first time…

Looking MUCH better

Once we did the initial test fit, we were both super motivated to see the project through to the end. Once it was finished, Liz commented that it was one of the nicest stitching machines she had ever used. I have to agree, it is a superb machine.

As much as I love that 66, we didn’t “need” it, and honestly, we have so many 66’s that it wouldn’t have seen any use. Machines in cases are easy to store, machines in cabinets… Not so much! She needed a new home. Enter Michele…

Michele is a long time friend, and she was in the market for a classic Singer. “Have I got a deal for you!” The deal was sealed before she even sat down at the machine. I had posted pix and videos on Facebook and Michele was sold. We loaded up the Singer in Liz’s Rogue and made the delivery.

Michele is one happy girl with her classic Singer 66.

I think the smile on Michele’s face says it all… A good friend gets a good machine, that’s a win-win in my book.

Oh yes… I mentioned that on that day, I bought three machines, this 66, a 15-88, and a 201-2. Michele has the 66, my sister Sue has the 15-88, and my daughter in law Sara has the 201-2. All went to good homes!

Happy sewing!