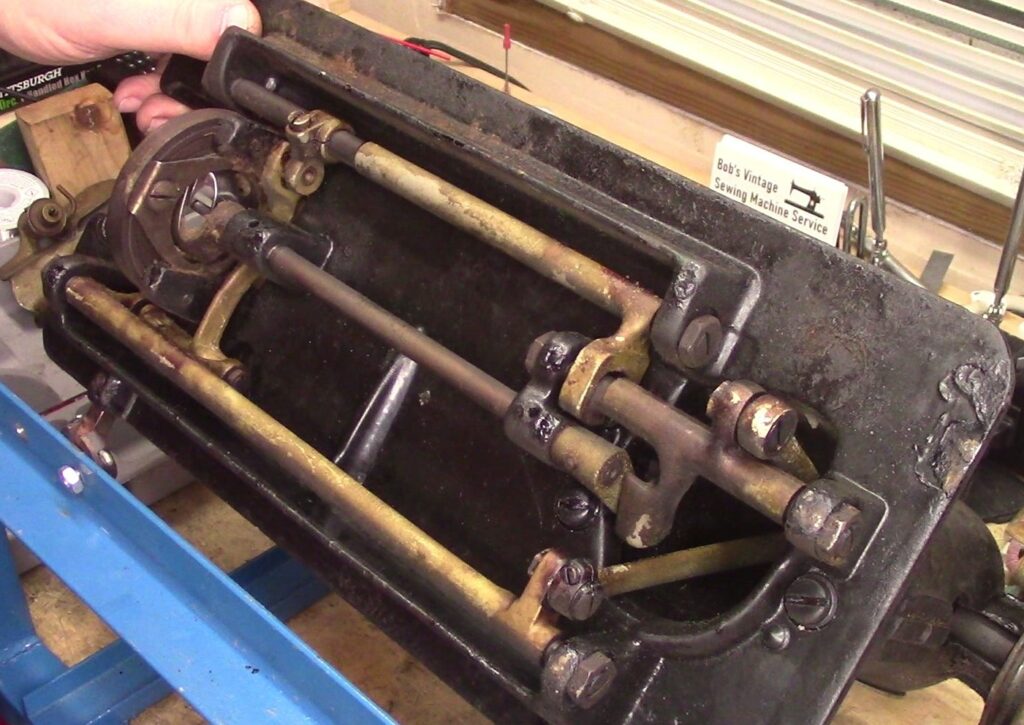

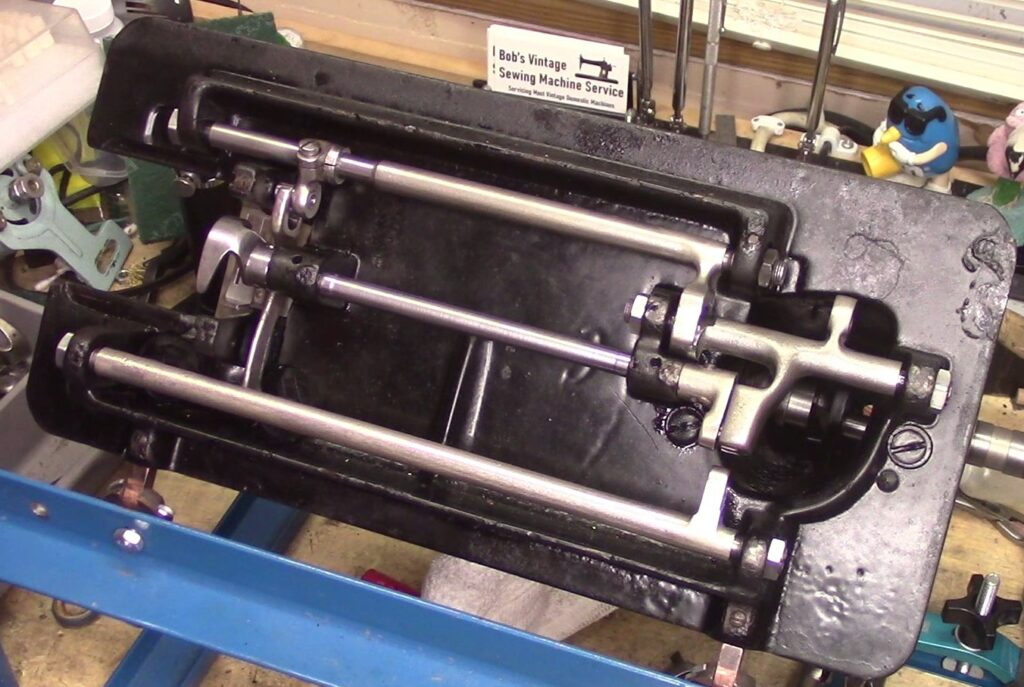

The picture shows the a before and after of the hook race / bobbin case and feed dogs of a Singer 15-30 from 1913. The machine belongs to a customer, now turned friend, who is just getting started in vintage sewing machines. I know technicians who, if they were presented this machine, would have said “Sorry, I don’t have the time to do THAT”…

Well… How much time HAS this machine taken? The rest of the machine was just as bad, if not worse. There was crud about 1/16″ thick on the rock shafts below the machine. The connecting rod and stitch length regulator fork were barely recognizable for the layers of grime. Everything in the needle bar area was covered in a thick layer of oil turned varnish that held all parts like glue. The disassembly took about 90 minutes, which is about an hour longer than it would usually take me to do that task. The presser bar alone consumed 20 minutes of my day getting it freed up. I had to drill out the pin that binds the crank to the oscillating hook shaft, one hundred nine years of crud has welded it secure.

The larger, non-polished components all went to the garage shop where I have a bench grinder with a wire wheel and after about an hour, the majority of those components were stripped of their protective crud coating. Final, detail cleaning, took place in the main shop and required several more hours of labor.

The hardware was tackled in the usual way; screw threads were cleaned with a wire wheel on a rotary tool, screws were chucked into the 1/2″ chuck on the bench motor so the heads could be cleaned and polished. The tapers of all six pivot screws were polished to a mirror like finish, as were the mating surfaces on the rock shafts. Every screw, every washer, every nut got the same level of attention – it all looks like new.

The reassembly required the same level of attention to detail. All threaded holes in the main casting were “chased” with taps so as to eliminate any potential contamination to the threaded connections. All metal to metal contact surfaces were polished to a mirror shine to minimize friction. The rock shafts were adjusted to eliminate lost motion (aka slop), yet to be free moving. Nothing was left to chance.

Total time in reassembly – I lost count after 4 hours. Is it worth the effort? Well, I can’t bill the customer for the actual hours I put into this machine, so why did I do it? I did it because I really don’t like the 15-30! I wanted to go nuts on a machine that’s decidedly NOT my favorite. In doing so, by going to the extreme on a machine that I really don’t like much, forced me to find new ways to extract every little bit of performance hidden in her iron body. An extreme rebuild on a model 66 or 99 would be a labor of love, but on a 15-30… It was hard work!

I really think I grew as a mechanic servicing this machine to this extreme degree. I enjoy challenging myself, and I really like getting my hands dirty. The filthy, disgusting mess that this machine was turned out to be the perfect vehicle to test my abilities.

As for my customer, her bill will be for a normal service…

What a good deed, done dirt cheap! Thank you for enabling another VSM devotee and for restoring another vsm even though it’s not one that you like. I really enjoyed reading this.

Ahh, you’re a good man, Bob. My 15-30 clean (SCRUB!) and replace has benefited greatly from your videos. You know that saying, ‘if this helps one person, I guess it’s worth all the swearing’? Well maybe that’s not exactly the saying. But I just could be the one who swore a little less because of your efforts. Thanks, Bob.

What a fantastic transformation! I have been watching your videos- you are a true craftsman. I wish I could send you this rusty boat anchor of a 27 I picked up at a yard sale for $20 last weekend. It’s lived in an attic for who knows how long. I’ve not done any restoration beyond moderate cleaning and oiling of a 15-91, 201, 99, 401, all of which were in much better shape to start with. I was discouraged at how much corrosion is on most parts of this 1899 27 machine. I was hoping it was “protective” crud. I just saw this post and it gave me a boost to see that it IS possible to salvage a total wreck of a machine. I won’t put it on the curb just yet